(1) The frequent breaking of clay leads to the frequent grinding and stopping of raw material, and the qualified rate of raw material KH is low, which affects the stability of thermal system of rotary kiln system.

(2) The rotating speed of the raw material roller mill is about 1350r/min, 93% of the rated speed, but the fineness of the raw material is still coarse (the residual size of 0.2mm screen is between 3% and 5%), which seriously affects the calcination quality of clinker and leads to high fCaO of clinker.

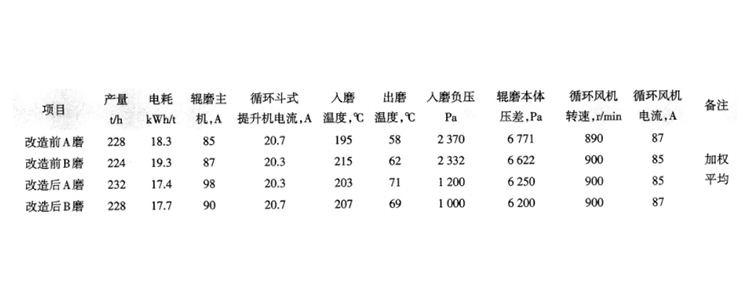

(3) The raw material roller mill output is low, about 190t/h, raw material process power consumption up to 22 ~ 23kWh/t.

(1) The clay feeding system is composed of clay round reservoir + silo + electronic belt measuring scale. Due to the large moisture and strong viscosity of clay, clay reservoir and silo are often covered and blocked, and clay is frequently broken, resulting in the qualified rate of grinding raw material KH is only 30% ~ 40%. Early in the warehouse around the installation of 4 air guns, the use of air guns when plugging material cleaning, but the phenomenon of broken material has not improved, artificial poke material frequently, labor intensity is large. Through analysis, it is concluded that the small size of discharging port of clay silo is the main reason for clogging and breaking of clay cover.

(2) When the residue of raw material 0.08mm screen is controlled at 14% ~ 16%, the residue of 0.2mm screen is about 3% ~ 5%, resulting in high fCaO of clinker, low pass rate and low clinker strength.

(3) A comprehensive inspection of the raw material roller mill found that the seal ring clearance of the classifier was large and the axial clearance was 30 ~ 40mm, resulting in coarse raw material fineness. At the same time, the static blade clearance of the classifier was uneven with different sizes, the maximum clearance was 120mm and the minimum clearance was 10mm, and part of the blades were loose and shifted.

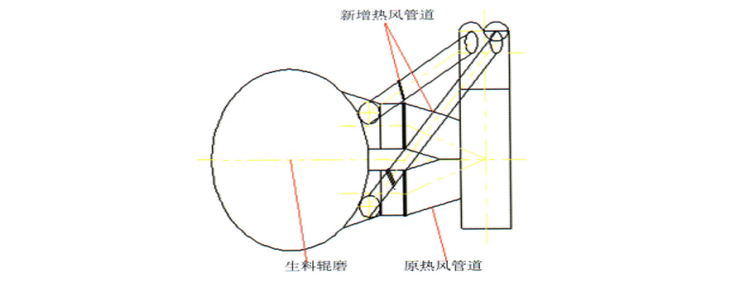

(4) The hot air pipe at the entrance of raw material roller mill has a corner of about 70°, which has more material and greater resistance. The negative pressure at the entrance of raw material roller mill is about -2000Pa.

(1) The width of the belt scale is changed from 1.2m to 1.6m, the width of the feeding port of the clay silo is expanded from 1.0m to 1.4m, at the same time, the belt scale is equipped with a broken material induction signal switch, and the silo is equipped with two electric vibrators. When the belt scale is broken, the induction switch gives the electric vibrator a start signal, the electric vibrator starts to clean the cover material, greatly reducing the phenomenon of broken material. The qualified rate of the raw material KH was greatly increased from 30% ~ 40% to 70%.

(2) The sealing ring of the powder separator is processed. Extend the inner side of the upper sealing ring. Lengthening 30mm for the first time, the speed of the classifier is reduced to 1200r/min, and the raw material is reduced to 2%-3%. The second time to lengthen 30mm, the speed of the powder separator is reduced to 1050r/min, raw material 0.2mm sieve residue is reduced to 1% ~ 2%.

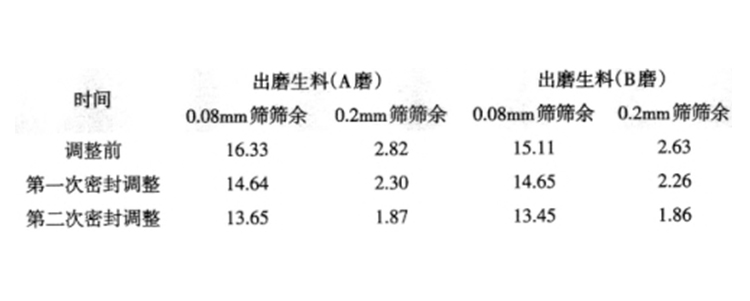

(3) Adjust the static blade clearance and fix the connection. According to the wind speed control between the static blades of the powder classifier is about 18m/s, the static blade clearance is determined to be 40mm, the static blade clearance of the powder classifier is uniformly adjusted, and all the static blades are welded and reinforced with steel bars to prevent displacement. The comparison of raw material fineness changes before and after adjustment of powder separator is shown in Table 1.

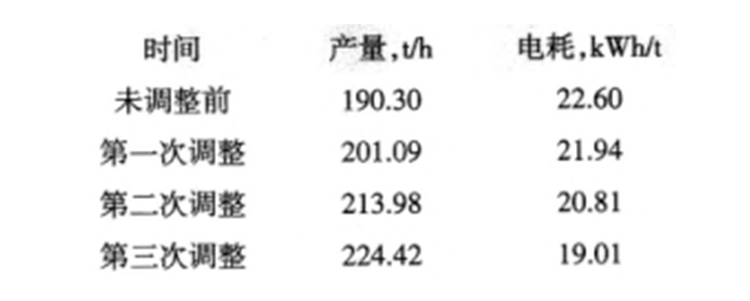

(4) By increasing the loading pressure of raw material roller mill, reducing the particle size of limestone, reducing the height of retaining ring, and improving the output of raw material roller mill. The loading pressure increased from 8.0mpa to 9.0mpa. The particle size of milled limestone decreases from 80mm to 70mm and then from 70m to 60mm. The height of the baffle ring first drops from 110mm to 90mm, then from 90mm to 80mm, and finally from 80mm to 70mm. The corresponding current drops from 130A to 110A, from 110A to 100A, from 100A to 90A. The output of raw material roller mill has been greatly improved. The adjustment process and effect are shown in Table 2.