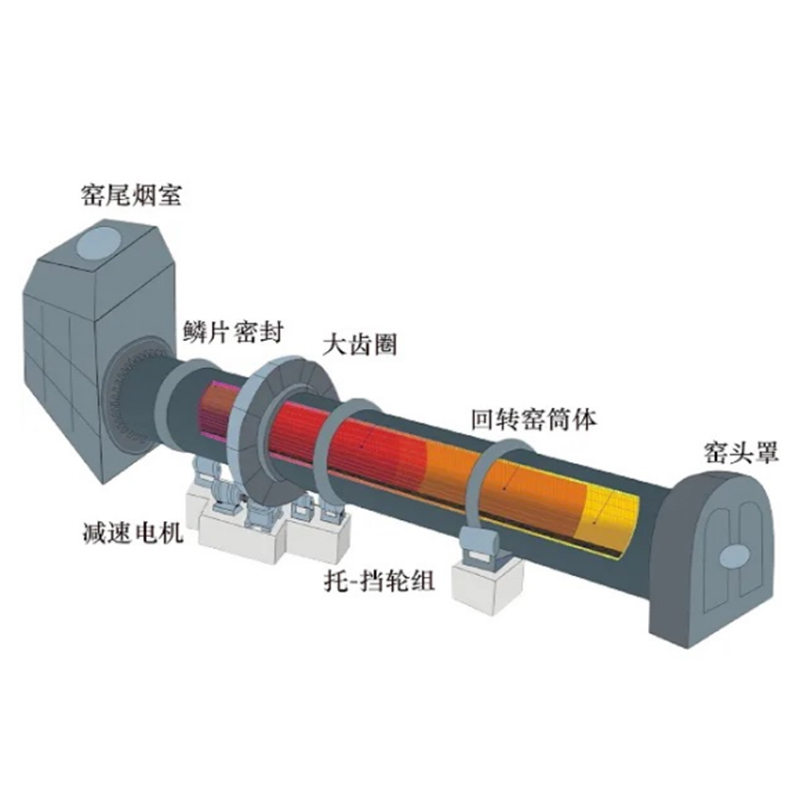

The pellets are roasted and consolidated in a rotary kiln.

Normal residence time of materials in rotary kiln: 25 ~ 35min

The roasting temperature of rotary kiln is 1300 ~ 1350 ℃. The rotary kiln head (discharging end) is provided with a burner for heating, and the high temperature exhaust gas of the cooling section I of the ring cooler is fed into the kiln as secondary air. The preheating ball rolls in the kiln with the rotation of the kiln body, and fully contacts with the high temperature hot air flow, so as to achieve the purpose of uniform roasting.

After the pellets were roasted at high temperature for 25-30 min in the rotary kiln, part of magnetite was oxidized into Fe203 microcrystalline recrystallization, and most of hematite grains gradually grew up, recrystallized and formed crystal Bridges at high temperature. Meanwhile, part of low melting point compounds produced at high temperature made the pellets more compact and increased the strength significantly. Up to 2500N/ ball above.

|

产品规格 |

生产能力 |

主电机 |

主减速机 |

重量 |

||

|

型号 |

功率(kw) |

型号 |

速比 |

|||

|

φ1.8x26 |

72 |

JZT2-72-4 |

30 |

JZQ750-1-Ⅰ |

48.57 |

66 |

|

φ2.2x45 |

98.4 |

JZT82-6 |

55 |

ZA125 |

93.93 |

104 |

|

φ2.5x50 |

180 |

ZT3-72-4 |

30 |

ZS145-9-Ⅴ |

122.8 |

173 |

|

φ3x48 |

700 |

ZSN4-280-21 |

110 |

MSY56-28-Ⅱ |

28 |

244 |

|

φ3.2x50 |

1000 |

ZSN4-280-21B |

160 |

MSY56-28-Ⅱ |

28 |

252.4 |

|

φ3.5x54 |

1500 |

ZSN4-3156-092 |

220 |

ZSY500-40-Ⅴ |

40 |

368 |

|

φ3.9x56 |

2000 |

Z4-280-32BTH |

250 |

ZSY560-40-Ⅰ |

40 |

417 |

|

φ4x60m |

2500 |

ZSN4-355-09Z |

315 |

ZSY630-35.5-Ⅰ |

34.6 |

523 |

|

φ4.3x60m |

3000 |

ZSN4-355-12 |

375 |

ZSY710-40 |

40 |

553 |

|

φ4.8x75m |

5000 |

ZSN4-400-92 |

630 |

JH710-40 |

42 |

841 |