The rotary kiln has the characteristics of simple structure, reliable operation and easy control of the production process. Through technological innovation, the rotary kiln calcination system equipment adopts domestic and foreign advanced hydraulic stopper device, metering plunger pump with high metering accuracy, high-precision speed regulating valve and contact graphite block sealing device and other domestic advanced equipment. technology. The kiln head can use industrial TV to watch the fire, the process flow simulates the fluorescent screen, and the calcination belt uses an infrared scanner to directly reflect the calcination status of the calcination belt on the computer. These new technologies are intuitive, easy to operate, and reliable to use. The thermal system is stabilized and the equipment operation rate is improved. Compared with equipment of the same specification, the output is increased by 10%, and the heat consumption is reduced by 15%.

Uses of Zinc Oxide

(1) After adding active zinc oxide to the rubber compound, the rubber has good wear resistance, tear resistance and elasticity.

(2) Zinc oxide is used as a white pigment. Because active zinc oxide has good activation properties, it has been more and more widely used in rubber products. For example, in V-belts, it can not only replace ordinary zinc oxide in the same amount, but also reduce 1/2-1/3 of the zinc oxide. The dosage can make the various performance indicators of the rubber stable, the vulcanization performance is not affected, and the production cost is reduced.

(3) Fine-grained zinc oxide can be used as a medicine.

(4) Due to the strong ability of zinc oxide to absorb ultraviolet rays, people are more and more used in the coloring of paints, inks, and varnished cloth, as a printing resist in the printing and dyeing industry, and in the match industry to neutralize the acidity of kraft glue and increase the adhesiveness. Effect, the pharmaceutical industry is used as a raw material for adhesive plaster, and it is also used for pigments.

(5) Zinc oxide is also used in pressure-sensitive, photocatalysis, photoelectrode, paint, color TV development and other fields.

The rotary kiln has the characteristics of simple structure, reliable operation and easy control of the production process. Through technological innovation, the rotary kiln calcination system equipment adopts domestic and foreign advanced hydraulic stopper device, metering plunger pump with high metering accuracy, high-precision speed regulating valve and contact graphite block sealing device and other domestic advanced equipment. technology. The kiln head can use industrial TV to watch the fire, the process flow simulates the fluorescent screen, and the calcination belt uses an infrared scanner to directly reflect the calcination status of the calcination belt on the computer. These new technologies are intuitive, easy to operate, and reliable to use. The thermal system is stabilized and the equipment operation rate is improved. Compared with equipment of the same specification, the output is increased by 10%, and the heat consumption is reduced by 15%.

Equipment composition

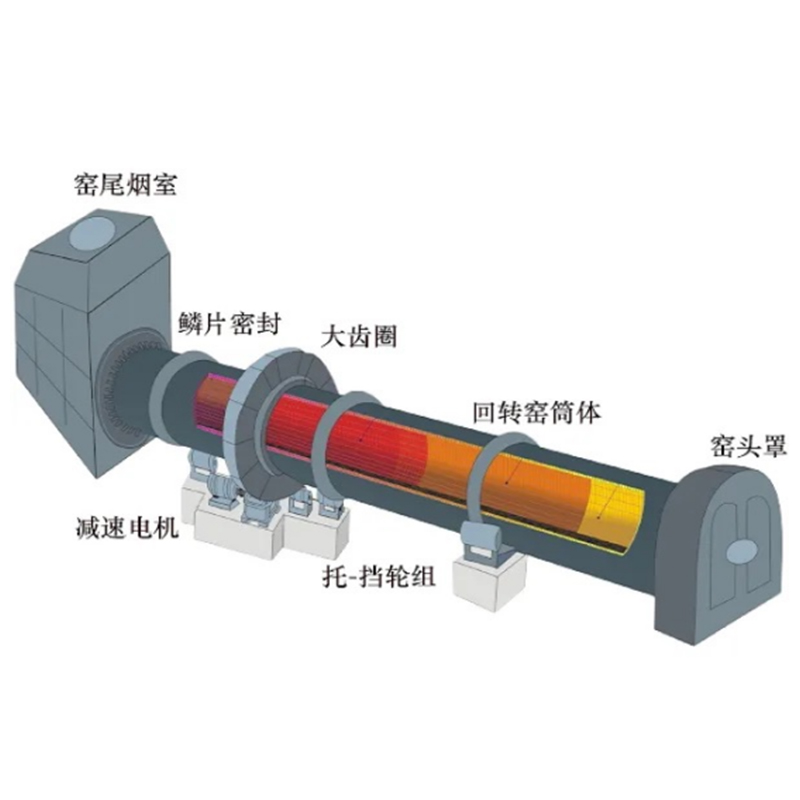

Zinc oxide rotary kiln is composed of cylinder body, supporting device, supporting device with tyre ring, transmission device, movable kiln head, kiln tail sealing device, combustion device and other components.Zinc oxide rotary kiln process

First, the ore powder, coal and water are prepared in a certain proportion and then sent to the ball making machine, and the balls are sent to the kiln tail. 12m or so, 650-700 degrees) and then enter the medium temperature section (about 18m, 700-850 degrees) and finally enter the high temperature section (about 18m, 850-1100 degrees, 907 degrees is the boiling point of Zn). The kiln keeps rotating, and a large and thick yellow flame is generated on the turning material surface in the high temperature section, that is, zinc vapor and various metal vapors. At the same time, it reacts with the remaining oxygen in the kiln to generate ZnO dust, but due to the fast air volume and wind speed (3-4m/s), it reaches the oxidation sedimentation chamber at once.

|

产品规格

Specifications |

窑体尺寸 Kiln size |

电机功率

Motor power |

总重量

Total weight |

||||

|

直径 diameter(m) |

长度 length(m) |

斜度 slope(%) |

产量 capacity(t/d) |

转速 Rotating speed(r/min) |

|||

|

Φ2.5×40 |

2.5 |

40 |

3.5 |

180 |

0.44-2.44 |

55 |

149.61 |

|

Φ2.5×50 |

2.5 |

50 |

3 |

200 |

0.62-1.86 |

55 |

187.37 |

|

Φ2.5×54 |

2.5 |

54 |

3.5 |

280 |

0.48-1.45 |

55 |

196.29 |

|

Φ2.7×42 |

2.7 |

42 |

3.5 |

320 |

0.10-1.52 |

55 |

198.5 |

|

Φ2.8×44 |

2.8 |

44 |

3.5 |

450 |

0.437-2.18 |

55 |

201.58 |

|

Φ3.0×45 |

3.0 |

45 |

3.5 |

500 |

0.5-2.47 |

75 |

201.94 |

|

Φ3.0×48 |

3 |

48 |

3.5 |

700 |

0.6-3.48 |

100 |

237 |

|

Φ3.0×60 |

3.0 |

60 |

4 |

800 |

0.3-2 |

100 |

310 |

|

Φ3.2×50 |

3.5 |

50 |

4 |

1000 |

0.6-3 |

125 |

278 |

|

Φ3.3×52 |

3.3 |

52 |

3.5 |

1300 |

0.266-2.66 |

125 |

283 |

|

Φ3.5×54 |

3.5 |

54 |

3.5 |

1500 |

0.55-3.4 |

220 |

363 |

|

Φ3.6×70 |

3.6 |

70 |

3.5 |

1800 |

0.25-1.25 |

125 |

419 |

|

Φ4.0×56 |

4.0 |

56 |

4 |

2300 |

0.41-4.07 |

315 |

456 |

|

Φ4.0×60 |

4 |

60 |

3.5 |

2500 |

0.396-3.96 |

315 |

510 |

|

Φ4.2×60 |

4.2 |

60 |

4 |

2750 |

0.41-4.07 |

375 |

633 |

|

Φ4.3×60 |

4.3 |

60 |

3.5 |

3200 |

0.396-3.96 |

375 |

583 |

|

Φ4.5×66 |

4.5 |

66 |

3.5 |

4000 |

0.41-4.1 |

560 |

710.4 |

|

Φ4.7×74 |

4.7 |

74 |

4 |

4500 |

0.35-4 |

630 |

849 |

|

Φ4.8×74 |

4.8 |

74 |

4 |

5000 |

0.396-3.96 |

630 |

899 |

|

Φ5.0×74 |

5 |

74 |

4 |

6000 |

0.35-4 |

710 |

944 |

|

Φ5.6×87 |

5.6 |

87 |

4 |

8000 |

Max4.23 |

800 |

1265 |

|

Φ6.0×95 |

6 |

95 |

4 |

10000 |

Max5 |

950×2 |

1659 |

Changzhou **** Co., Ltd. Zinc oxide rotary kiln Φ4.2×60m