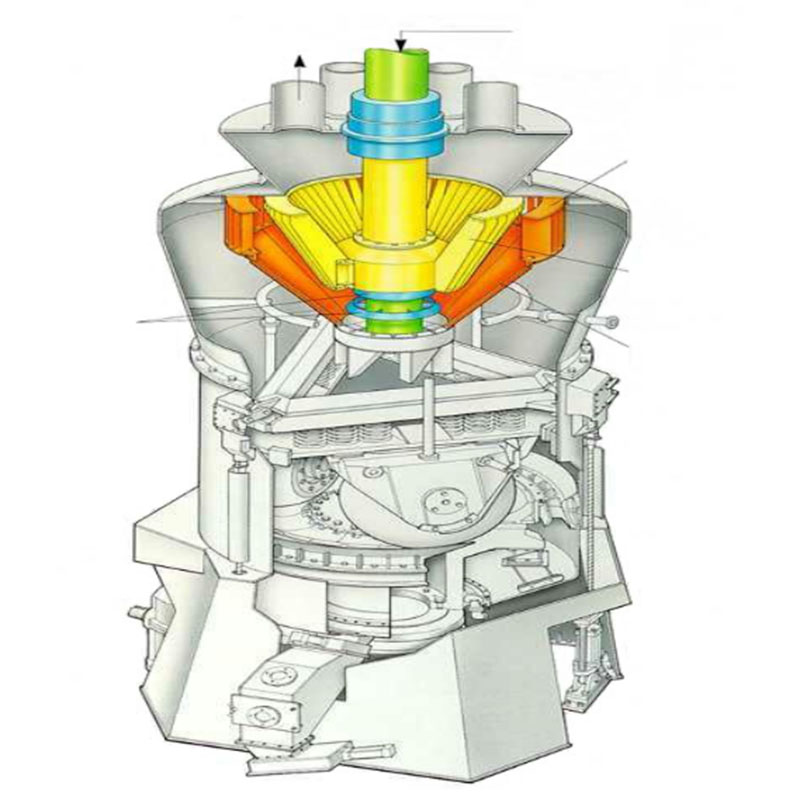

MPS series coal mill is a medium speed roller type coal mill. Its grinding part is composed of rotating grinding ring and three fixed and rotatable grinding rollers rolling along the grinding ring. The raw coal to be grinded falls from the coal falling pipe in the center of the mill to the grinding ring, and the rotating grinding ring moves the raw coal to the grinding roller by means of centrifugal force, which is grinded by the grinding roller. The grinding force is generated by the hydraulic loading system. Through the statically fixed three-point system, the grinding force ACTS uniformly on the three rollers. The force is transmitted to the foundation through the bottom plate through the grinding ring, grinding roller, press frame, pull rod, transmission disc, reducer and hydraulic cylinder (see figure 1-1). The grinding and drying of raw coal are carried out at the same time. The primary air enters into the surrounding area of the grinding ring uniformly through the nozzle ring, and the mixture of coal powder thrown out tangentially from the grinding ring is dried and transported to the separator on the upper part of the coal mill for separation. The coarse powder is separated and returned to the grinding ring for regrinding.

|

Model |

mps 130 |

mps160 |

mps190 |

Mps225 |

Mps245 |

Mps265 |

Mps290 |

|

capacity (t/h) |

10.5-15.5 |

18.4-25.2 |

29.1-37.9 |

43.8-56.8 |

63-76.6 |

76.6-84.1 |

96-108.9 |

|

Motor (kw) |

125-185 |

220-280 |

330-450 |

500-650 |

720-800 |

880-1000 |

1120-1250 |

|

diameter of grinding disc(mm) |

1300 |

1600 |

1900 |

2250 |

2450 |

2650 |

2900 |

|

speed(r/min) |

31.9 |

28.7 |

26.4 |

24.2 |

23.2 |

22.3 |

21.3 |

|

roller number(set) |

3 |

3 |

3 |

3 |

3 |

3 |

3 |