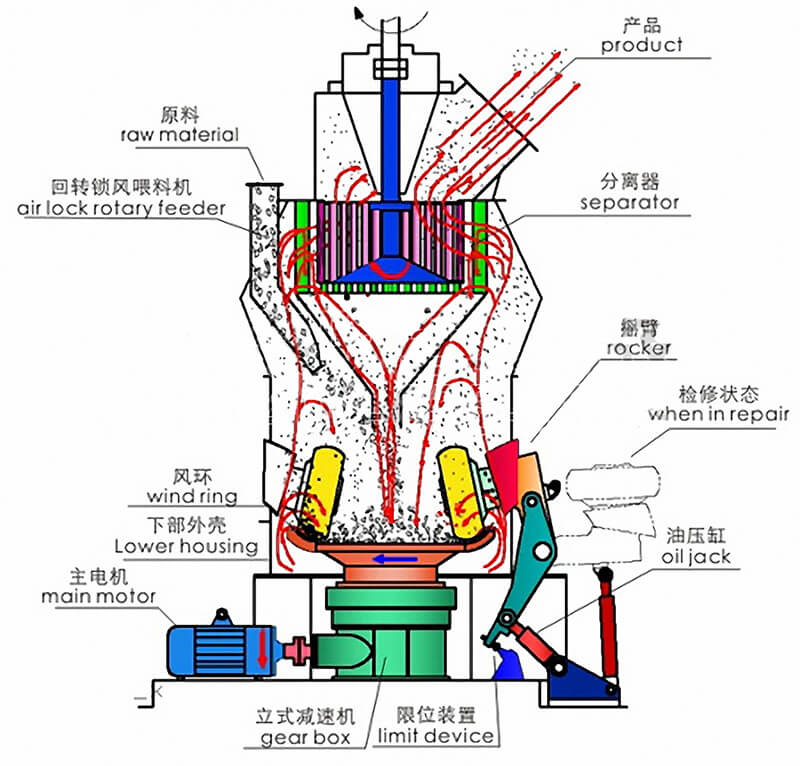

VRM vertical mills are also commonly referred to as roller mills, medium speed mills, etc. in different industries. The models are characterized by crushing, grinding, drying and grading, and can be used for various types of moisture, properties and hardness. The pulverization of the material to the required particle size is ideal for the current milling industry.

Cement raw material milling, slag micropowder production, calcium carbonate pulverization processing, pulverized coal preparation station, gypsum powder processing, power plant desulfurization, phosphate rock grinding, metallurgical industry, ultra-fine grinding industry, other non-metallic mineral powder, etc.

The coal mill is mainly composed of machine base, casing, column, separator (selector), reducer, grinding device (grinding disc and grinding roller), rocker arm device, hydraulic loading device, sealed pipeline system and slagging device. , operating platform and other components. The supporting equipments include thin oil lubrication station, hydraulic oil station, dry oil station, main motor and electrical control cabinet.

Application: Steel plant blast furnace slag, steel slag; power plant slag; phosphorus slag and other solid waste recycling.

|

Model |

VRM2200S |

VRM2400S |

VRM2800S |

VRM3400S |

VRM3700S |

VRM4200 |

VRM4500 |

VRM4800 |

|

Capacity (t/h) |

15-20 |

24-28 |

50-70 |

70-85 |

90-110 |

110-140 |

130-150 |

150-200 |

|

Max. Feeding size(mm) |

1-10 |

|||||||

|

Slag moisture(%) |

<15 |

|||||||

|

Specific surface area(㎡/kg) |

≥420 |

|||||||

|

Final moisture (%) |

<1 |

|||||||

|

Main motor power (kW) |

630 |

900 |

1800 |

2500 |

3350 |

3800 |

4500 |

5400 |

Slag grindability index (Bond) ≤25kwh/t

Steel slag grindability index (Bond) ≤30kwh/t

The capacity will decrease 30-40% when grinding steel slag.