The mill process optimization is the best way to improve the production and to reduce the energy consumption.

Sorting out broken and deformed balls, ball charge classifications and gradations will improve the mill operation efficiency and to reduce the overstock of grinding balls.

The mill process optimization is the best way to improve the production and to reduce the energy consumption.

Sorting out broken and deformed balls, ball charge classifications and gradations will improve the mill operation efficiency and to reduce the overstock of grinding balls.

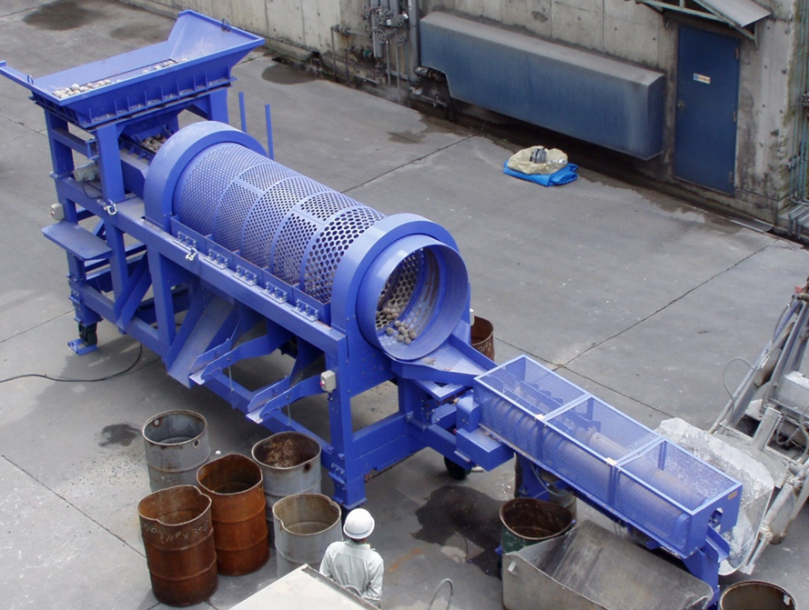

BALL SORTING MACHINE

The ball sorting machine allows sorting of the balls from the first or second compartment of a Ball Mill. In order to sort the balls, there are two different drums available and they can easily and safely be swapped/changed. As standard, the ball sorting machine is supplied with one sorting-drum for 1st or 2nd chamber balls. The second sorting-drum is optional and be purchased separately.

It is a fact that a Ball Mill circuit is a grinding process by the help of grinding media, especially by Hi Cr Balls. The proper ball charge and grinding balls are one of the key points of the grinding process. So, the user must be sure about the proportion of each media size in the ball mill with the right quantity and distribution.

Why Sorting of the Balls?

As the time goes by, the distribution/proportion of the grinding ball sizes inside the ball mill gets changed, as a natural outcome of wear phenomena and/or breakage of the balls. Therefore the grinding efficiency drops. Every ball mill has a unique process result due to its physical condition, size, circuit, ground material, finish product type and auxiliary equipment. There is, however, a global thumb-rule for every ball mill that its best working condition is achieved by proper ball charge distribution determined by process experts (classification of 2nd chamber ball charge in 2 chamber mills is a good example of this fact). The importance and effect of proper ball charge distribution are proved by many lab tests as well as real industrial applications.

To sort the balls manually requires a big amount of time costing money and labor.

For example;

A ball mil with 4,0 m diameter will have the following figures;

If the mill has 2 chambers:

there are approximately 3,6 million balls available in the mill

If the mill is mono chamber due to Roller Press:

there are approximately 4,0 – 4,2 million balls available in the mill.

It is essential to keep the best pre-determined ball charge distribution inside the ball mill as much as possible for its efficiency.

For this purpose, generally, the recommendation is to sort 1st compartment ball charge once a year and 2nd compartment ball charge every 2 years.

Ball Sorting Machine general dimensions:

overall length : 10.648 mm

overall width : 2.528 mm

overall height : 2.760 mm

two independent wheels for precise positioning of the ball sorting machine

a total of 8 outlet chutes

one feeding hopper with vibrating feeder

total weight: approx. 6.800 kg with feeding hopper

|

TECHNICAL DATA |

|||

|

CONTENTS |

UNIT |

PARAMETER |

|

|

PERFORNMANCE |

diameter |

mm |

Φ750 |

|

Angle |

° |

0-12° |

|

|

Number |

set |

1 |

|

|

length |

mm |

6000 |

|

|

Balls diameter |

mm |

15-100 |

|

|

Design capacity |

t/h |

24 |

|

|

GEAR-MOTOR |

Model |

|

YSCL801-4 |

|

Power |

kW |

5.5 |

|

|

Speed |

r/min |

23-55 |

|

|

Quantity |

|

1 |

|

|

Vibrating feeder

|

MODEL |

|

GZ2F |

|

POWER |

kW |

0.22 |

|

|

Capacity |

T/h |

0-30t/h |

|

|

Discharge Size |

Groove width |

mm |

200 |

|

Quantity |

|

10 |

|

|

OUTLINE DIMENSIONAL |

mm |

10648×2528×2760 |

|

|

TOTAL WEIGHT (WITHOUT BALLS) |

t |

~8.5 |

|

|

MAXIMUM LOAD BALLS |

t |

~6.8 |

|